Silicon Valley’s Trusted Partner for Aerospace Wiring

EWIS & MIL‑SPEC HARNESS ENGINEERING

Specification‑grade EWIS for development‑phase aircraft

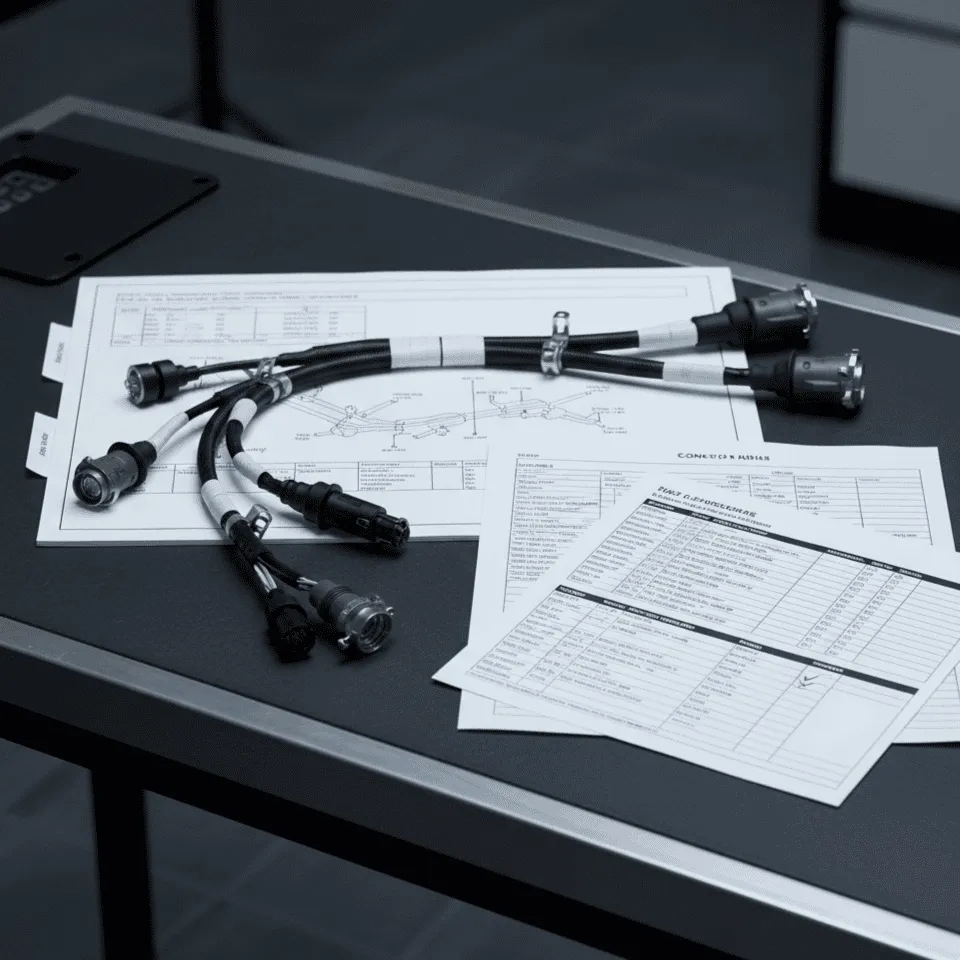

Hangar1 Aerospace defines and documents your EWIS and Mil‑Spec harnesses so your prototypes wire‑up once and test cleanly. We specialize in harness definition, specification packages, test readiness, and documentation discipline—not field installation.

Typical scope: harness spec package, prototype build support, test harnesses, and revision‑controlled documentation.

Harness definition, spec, and test readiness

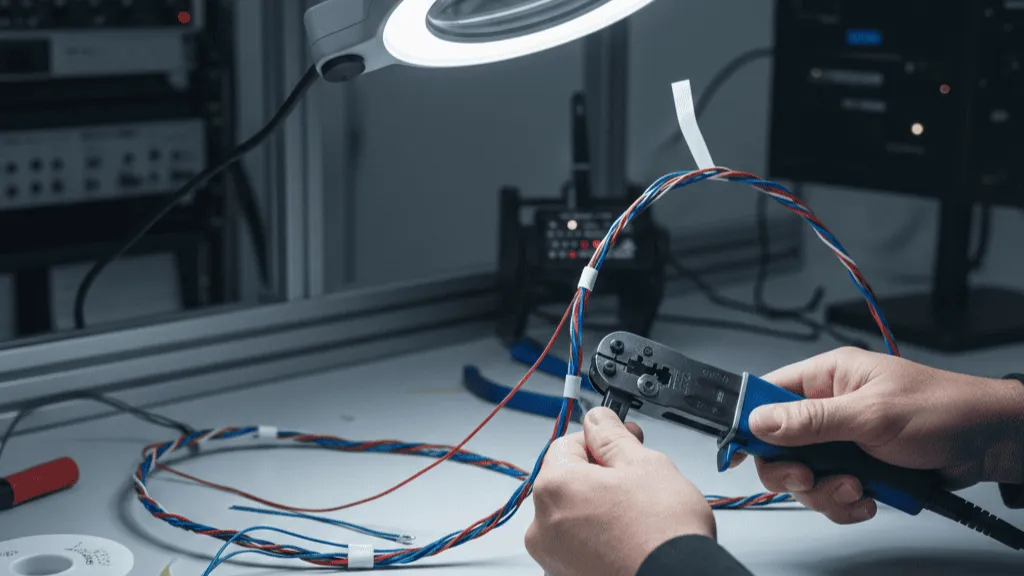

- Complete EWIS and harness bill of materials (BOM) with Mil‑Spec part selection

- Formboard‑ready harness drawings with connector tables and wiring details

- Continuity and insulation resistance test requirements for prototype harnesses

- Revision‑controlled documentation tuned for fast‑moving flight test teams

What We Deliver

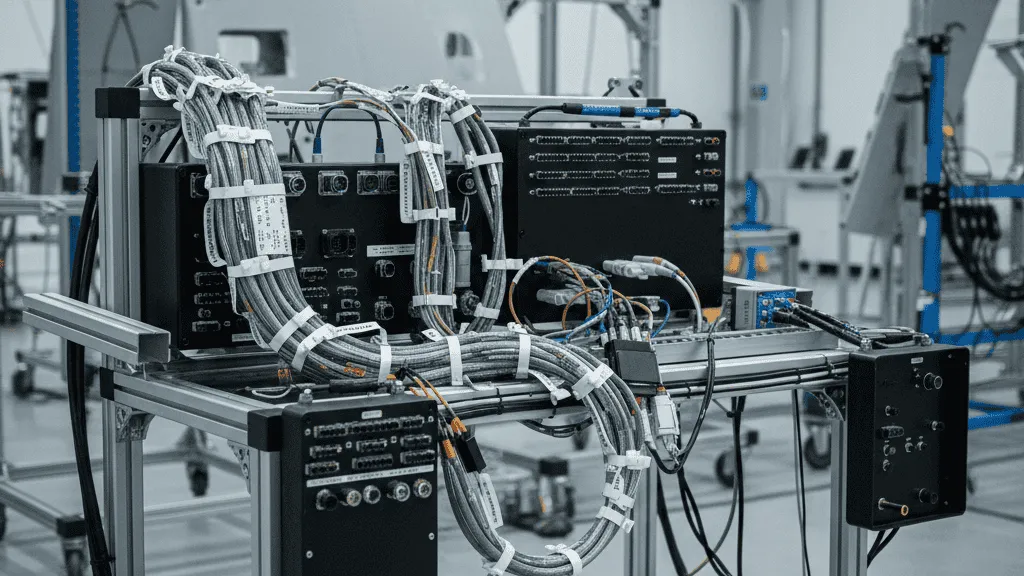

EWIS & harness engineering for test‑ready aircraft

Three tightly integrated service lines, all centered on disciplined harness definition—not field installation.

Harness specification packages

Engineering‑grade harness definitions that go straight into prototype build and certification workflows.

- System‑level EWIS topology and routing intent

- Connector selection, keying, and contact allocations

- Wire gauge, color, and insulation spec per circuit

- Shielding, grounding, and separation guidelines

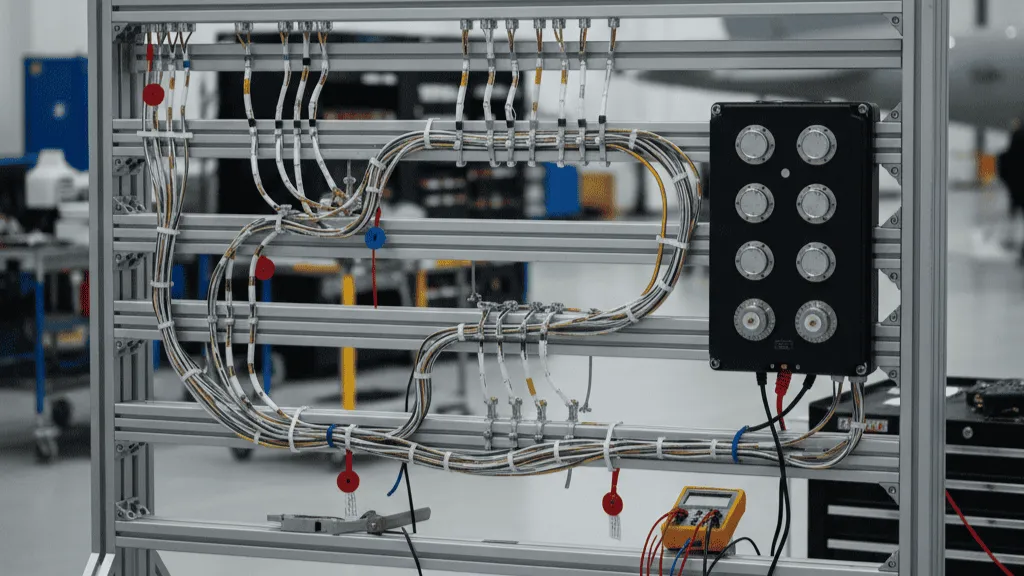

Prototype & test harness support

De‑risk early ground and flight test by engineering harnesses around your instrumentation and avionics stack.

- Prototype harness drawings for shop‑floor build

- Test harnesses for LRUs, LRMs, and avionics racks

- Interface harnesses for benches and simulators

- Ground test fixtures for continuity and IR testing

Documentation & revision control

Keep harness definitions aligned with aircraft configuration as programs iterate quickly toward certification.

Drawing trees, part numbering, and change logic

Formal ECN / ECR friendly deliverables

Traceability documentation from requirements to harness level

Release packages tailored for your PDM/PLM

Platforms

EWIS tuned to demanding mission profiles

From rotorcraft vibration environments to business aviation avionics upgrades and new autonomous cargo platforms, we align harness design with how the aircraft will actually be flown and tested.

Helicopter & rotorcraft design and refit programs

Harnesses engineered for high vibration, maintenance access, and mission equipment growth.

Mission kit development and sensor harness integration

Power system distribution and protection coordination

Routing for removable cowlings, doors, and panels

Business & private aircraft ADS‑B & avionics

Clean, cert‑ready harness packages for ADS‑B upgrades, cockpit modernization, and connectivity systems.

Harnesses for transponders, GPS, and ADS‑B solutions

Integration with existing power and breaker panels

Ground and flight test harnesses programs for new avionics

Autonomous freight & air taxi platforms

Harness architectures that connect flight computers, power systems, and sensing across distributed airframes.

- Redundant power and signal paths for autonomous control

- High‑bandwidth data harnessing for sensors and comms

- Ground test fixtures for system‑level integration labs

Process

From RFQ to revision‑controlled harness set

A lightweight, engineering‑driven workflow that keeps wiring, harnesses, and documentation synchronized as the aircraft evolves.

Step 01

Requirements & RFQ intake

We review aircraft architecture, LRUs, mission profile, cert targets, and existing EWIS or harness data. You receive a clear scope, schedule, and deliverables definition suitable for internal approval.

Step 02

EWIS & harness architecture

We define system‑level wiring, signal groups, grounding strategy, and harness break‑points to match your installation and maintenance philosophy.

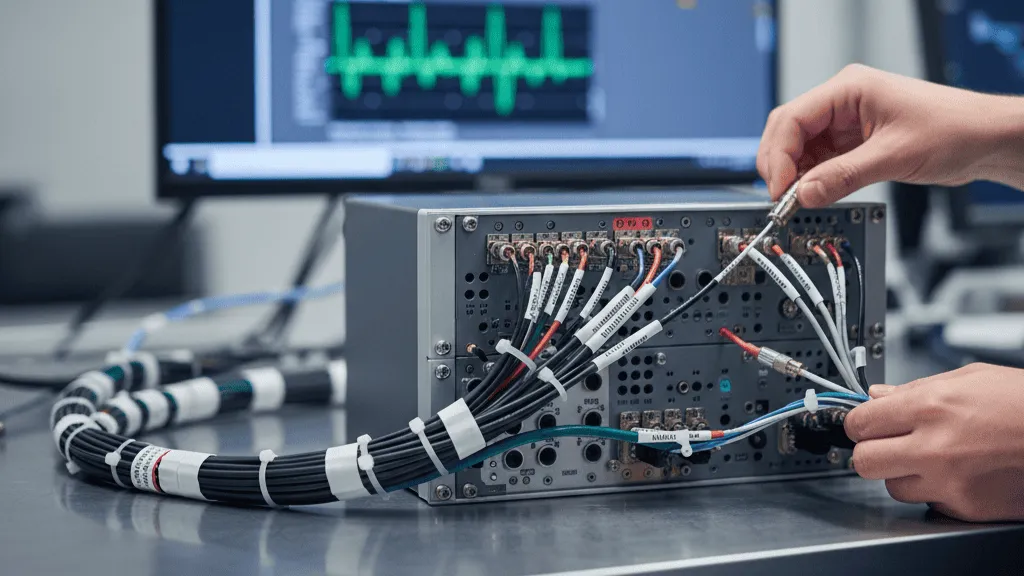

Step 03

Detailed harness definition

Connector tables, pin assignments, wire lists, shielding, splices, and test points are engineered into complete harness drawings and BOMs suitable for formboards.

Step 04

Test & documentation release

We define continuity and insulation resistance tests, ground test fixtures, and release a revision‑controlled documentation set aligned with your PLM or drawing standards.

Standards & Deliverables

Mil‑Spec harness engineering you can certify against

We work within your house standards or align to common aerospace and military references. The emphasis is always on traceable, test‑ready documentation.

Typical reference standards

- EWIS and harness design aligned with FAA 25.1701+ intent where applicable

- Mil‑Spec and aerospace components (e.g., MIL‑DTL‑38999, AS50881 principles, AS22759 wire families)

- ADR and ARINC‑style interface considerations for avionics integration

- Company‑specific drawing and part‑numbering standards when provided

Harness deliverable set

- Harness assembly drawings with connector tables, splice callouts, and shielding terminations

- Wire lists including gauge, color, insulation, length basis, signal names, and destination references

- BOMs with Mil‑Spec components, backshells, boots, labels, clamps, and protective coverings

- Ground, continuity, and insulation‑resistance test procedures and acceptance criteria

- Ground test fixture concepts and harness‑to‑test‑rack interface definitions

- Configuration index, change history, and revision‑controlled PDF/neutral formats for release

Data & handover formats

- Drawing output in PDF plus native CAD where available

- Tabular data in CSV/Excel for import into ERP, PLM, or harness build software

- Clear mapping of harness IDs to aircraft zones and effectivity

- Optional design notes summarizing critical assumptions and test dependencies

About Hangar1 Aerospace

Focused on wiring the development fleet, not the hangar floor

Hangar1 Aerospace is an engineering partner dedicated to EWIS and Mil‑Spec harness definition for development‑phase aircraft programs. We sit between avionics, systems, and production—translating intent into precise harness packages, test harnesses, and documentation that your build teams can trust.

Our projects range from one‑off prototype harness sets to full fleet harness definition and change management across rapid design iterations.

Why teams bring us in

You need disciplined harness documentation before committing to hardware or installation labor.

Your avionics stack and mission systems are evolving rapidly and need revision‑controlled harness definitions.

You want test harnesses and ground fixtures engineered alongside the EWIS—not as an afterthought.

Your internal team is overloaded with systems and certification tasks and needs focused harness engineering capacity.

Remote and On-site support for San Jose and South Bay aerospace labs.

REQUEST RFQ & Contact

Share your harness scope for an engineering‑grade RFQ

Tell us about your aircraft, avionics stack, and schedule. We’ll respond with a concise list of assumptions, deliverables, and milestones so your team can evaluate fit quickly.

Helpful to include: platform type, cert path; e.g. AS50881, AC 43.13, or IPC-WHMA-A-620 (if known), number of harnesses, rough circuit count, avionics vendors, and target test dates.

By submitting this form you’re contacting us for engineering services around EWIS and harness design, not installation labor.

© 2026 Hangar1 Aerospace. EWIS & Mil‑Spec harness engineering for development‑phase aircraft programs.

Powered by OptiReachMedia

Hangar 1 Aerospace

7228 Via Sendero

San Jose CA 95135

RFQ Direct: 650-291-0043